JP can supply gas springs for almost all applications, but how to choose the perfect gas spring for your case? By reading this article, you will be able to choose the right one by clarifying what type of gas spring you need, what function you want to achieve, how much force is required, and the total length of the gas spring, etc.

First, we would like to know what your application is. In other words, which type of gas spring can meet your desired function?

There are different types of gas springs. The most common type you probably see in daily life is a compression gas spring. And we also have locking gas spring, Tension gas spring, and gas dampers used in special applications.

In your case, do you want to open the lid with as little force as possible(figure a)? Or open automatically (figure c)? Or keep open/closed(figure b)?

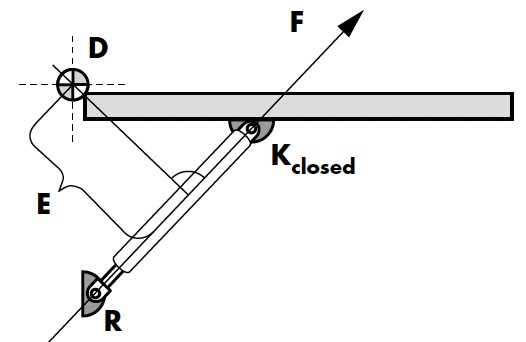

By following the instructions below, you will be able to find the suitable fixing points and the extended length and compressed length of the gas spring. Optimum fixing points are crucial for a gas spring to work effectively.

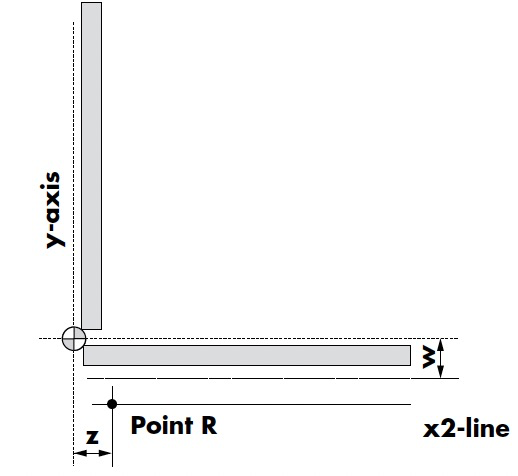

If lid weight is less than 20kg, point R is 20 mm from the bottom edge of the lid. That means W and Z are both 20 mm.

If the lid weight is more than 20kg, the point R distance from the bottom edge of the lid should be larger than 20 mm, from 20~80mm.

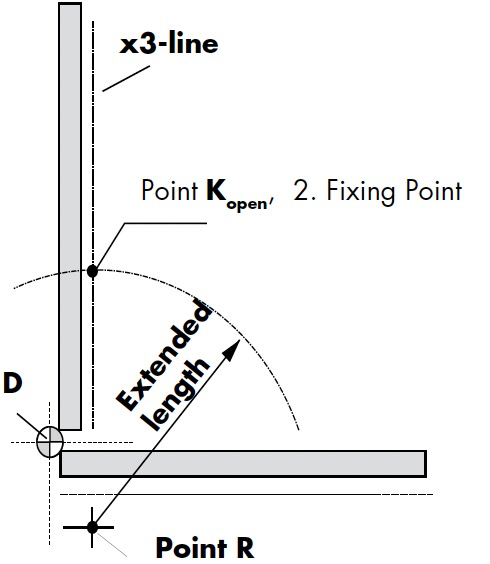

The extended length of the gas spring should correspond to approx. 2/3 of the lid, this is the best practice from hundreds of real application cases we have in the past decades.

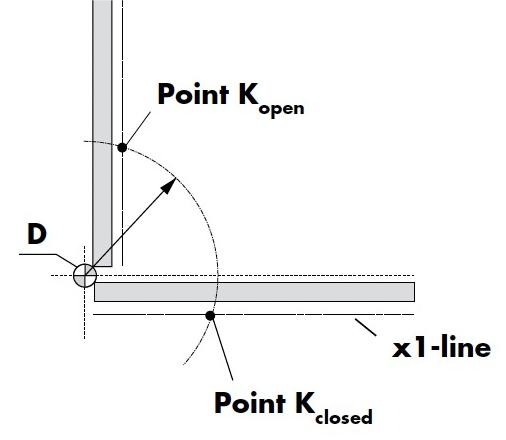

Now draw a circle around point R. The radius of this circle is the extended length you have calculated above. The point where the circle cuts across the lid edge is point Kopen.

Point R and point Kopen are the points that fix both ends of the gas spring. And the distance between R-Kopen is the extended length Le.

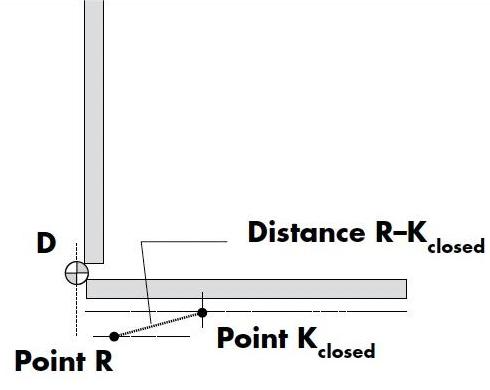

Firstly take the radius from pivot point D to point Kopen with the compasses, then draw a circle around pivot point D. The point where the cut crosses the lid bottom line is point Kclosed. The distance between fixing points R and Kclose is the length when the gas spring is entirely compressed(lid closed). Let’s say Lc

Le minus Lc is the minimum stroke required for your application. Make sure your stroke is at least 5-10mm long.

Stroke = Le – Lc + 5~10 mm

Now the total length of the gas spring and Point R and Point K to fix the gas spring, also the minimum stroke is determined.

Let’s move forward to the next step, to calculate the force.

The gas spring force required is relevant to the function you want to achieve. Should it assist the opening OR automatically open the lid OR stay in the open/closed position?

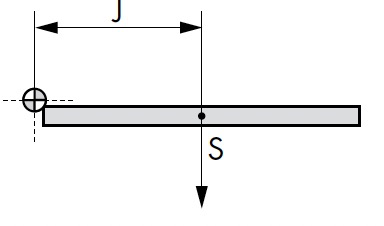

When the gas spring moment is equal to the lid gravity moment, the flap will

theoretically stay in this position.

F * E = S * J, the corresponding gas spring force is F=S*J/E.

The lid closes slowly by its weight: F<S*J/E

F>S*J/E

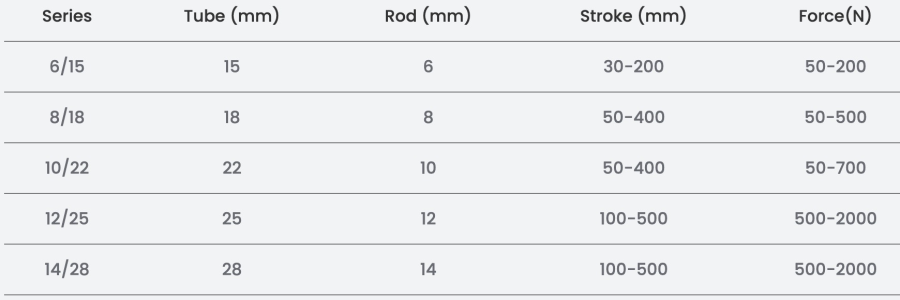

Following the instructions above, you have chosen the suitable Force F, Extended length Le, Stroke. Now we need to determine the Piston Rod diameter and Cylinder diameter.

Rod diameter and cylinder diameter have certain combinations. They are 6/15, 8/18, 10/22, 12/25, and 14/28. And each combination/series have preferred stroke and force. Please choose the series that matches your application best, or contact us for technical support.

The last thing we need to do is to choose the suitable end fitting.

Different end fittings are:

Ball joint types can be made with carbon steel, stainless steel, plastic, or composite material.

Eyelet types can be made with carbon steel, stainless steel, or zinc alloy.

Clevis type is usually made of carbon steel.

More detail please refer to: Gas spring end fittings and mounting brackets

You have finished reading this article and chosen the suitable gas spring for your application. Our experienced engineers are also ready to support you if you need technical support from us.

JP sets your brand to greater heights, from offering high-quality and expertly designed gas springs to getting comprehensive services from our experts. Let’s talk.

Copyright © 2022, JP. All rights reserved. Powered by MML.

*We respect your confidentiality and all information is protected.