What is a Gas Spring?

Gas springs (gas struts or gas shocks) are mechanical devices designed to store and release energy using compressed gas. They mainly consist of a sealed cylinder, piston, piston rod, etc.

When the gas spring is compressed, the gas inside the cylinder is compressed as well, to store potential energy. This potential energy is then released when the gas spring extends, exerting controlled force or assisting in lifting or supporting loads. Some typical applications are office chairs, automotive hoods, and hospital beds, etc.

Gas springs have several advantages including:

- Controlled operation: Gas springs can provide a smooth and controlled motion

- Low Maintenance: Requiring no lubrication or adjustment

- Constant Force: Near constant force, small K-factor. On the contrary, coil springs have big differences throughout the travel.

- Long service life: JP gas springs are designed to withstand high loads and harsh environments with a service life of up to 100,000 cycles

How Does Gas Spring Work?

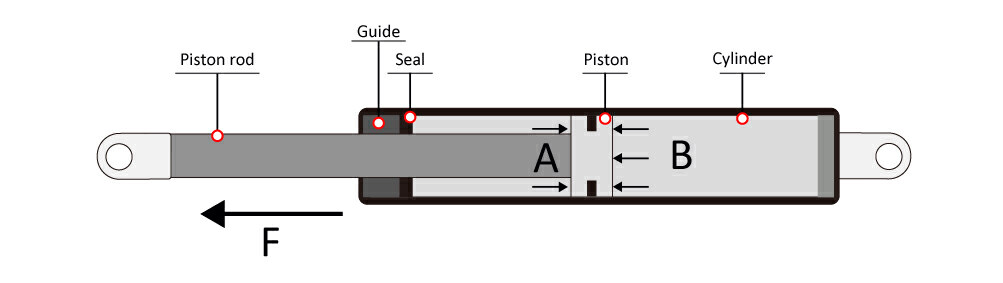

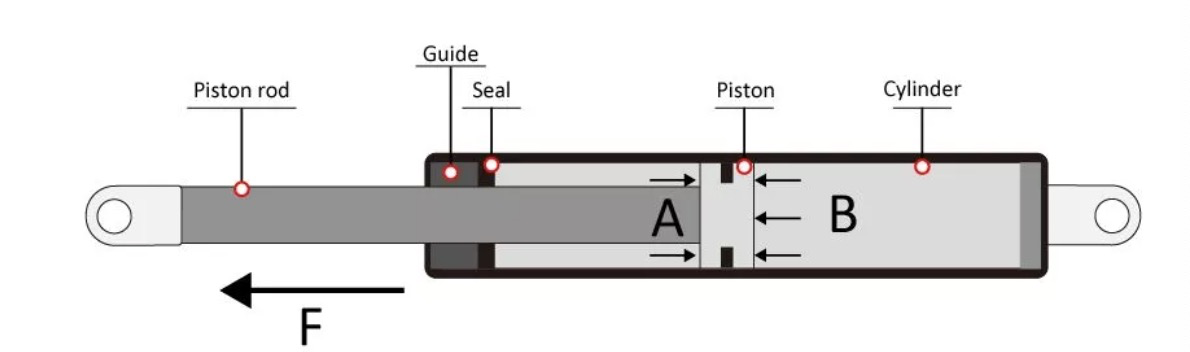

As you can see from the sectional view of a gas spring below, Area A is always a bit smaller than Area B, which is caused by the rod area. The surface area difference on both sides of the piston generates the force.

So, theoretically the force of a gas spring can be calculated by this simple formula:

F=P*(B-A)

P means the gas pressure inside.

B minus A means the area difference.

When gas spring compresses or extends, gas can move through a hole(or a valve) from one side to another, maintaining pressure on both sides. Also, the net compression or extension force will near-constant.

Applications of Gas Springs

Gas springs find applications in a wide range of industries, offering benefits such as improved safety, ergonomic functionality, and space optimization.

In the automotive industry, gas springs are utilized in trunk lids, hoods, and tailgates, providing convenient and effortless opening and closing mechanisms.

Furniture designers incorporate gas springs in chairs and adjustable desks, allowing users to easily adjust height and reclining positions.

Medical equipment, such as hospital beds and surgical tables, rely on gas springs for smooth and precise adjustments.

Aerospace and aviation industries utilize gas springs for cabin doors, baggage compartments, and seating mechanisms.

Industrial machinery, agricultural equipment, and countless other fields benefit from the use of gas springs, providing controlled motion and enhanced functionality.

Types of Gas Springs

Compression Gas Spring

This is the most popular gas spring with fixed force. It operates by compressing the gas in the cylinder to provide force in the extension direction.

They Widely used in various applications, such as: trunk, automotive hood&tailgate, RV and special vehicles, industrial and agricultural equipment, gaming machines, monitor brackets, furniture, etc.

Locking Gas Spring

The lockable gas spring differs from the compressed gas spring in that it can be locked at any position along the stroke, with a pin at the rod end. When the pin is pressed, it acts like a compressed gas spring; And when the pin is released, it locked on the stroke.

Some applications JP has worked with worldwide customers: hospital beds and furniture, passenger seats on the train, medical equipment, height-adjustable tables, adjustable sofa, etc.

Stainless Steel Gas Spring

316L or 304 Stainless Steel gas spring has the highest grade anti-corrosion characteristic, ideal to use in harsh environment applications such as marine, chemical, medical, and food industries.

Compression, locking, and tension gas springs can be made of 316L stainless steel if required.

Force adjustable Gas Spring

“Force Adjustable” means that the volume and pressure of the gas in the gas strut can be reduced via a valve to achieve the exact force suitable for your application.

Dampers

Gas damper is a motion control component with hydraulic oil inside; it can provide a damping effect in compression or extension directions or both. This type of gas spring is popularly used in lids, doors, covers, or any other object needed to move at a desired or controlled speed when given an external force.

Safety Locking Shroud Gas Spring

This type of gas spring has an additional safety locking shroud fitted on the rod side. The shroud can prevent the spring from compressing when the gas spring is fully extended. This mechanism can avoid potential injury when overload, misuse, or failure of the gas spring occurs.