When designing mechanical systems with moving parts, choosing between dampers and gas springs often confuses engineers. While both components deal with motion control, they serve completely different purposes in applications.

The core difference lies in their primary function: gas springs provide controlled lifting/lowering forces (energy storage), while dampers specifically control movement speed (energy dissipation). Gas springs actively move objects, whereas dampers passively slow existing motion.

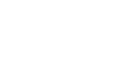

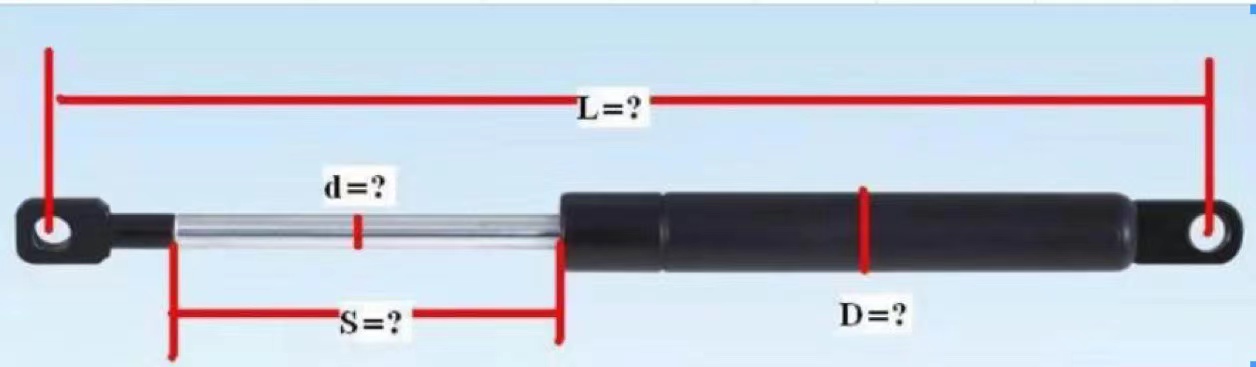

How Do Gas Springs Actually Work?

Gas springs store and release energy through compressed nitrogen:

-

Working Principle

- Sealed cylinder with nitrogen gas

- Compressed gas creates pushing force

- Force remains nearly constant through stroke

-

Key Characteristics

- Provide lifting/supporting force (50N-3000N typical)

- Maintain consistent pressure through stroke

- Self-contained (need no external power)

-

Typical Applications

- Automotive trunks/hoods

- Adjustable office chairs

- Medical equipment positioning

- Industrial machine covers

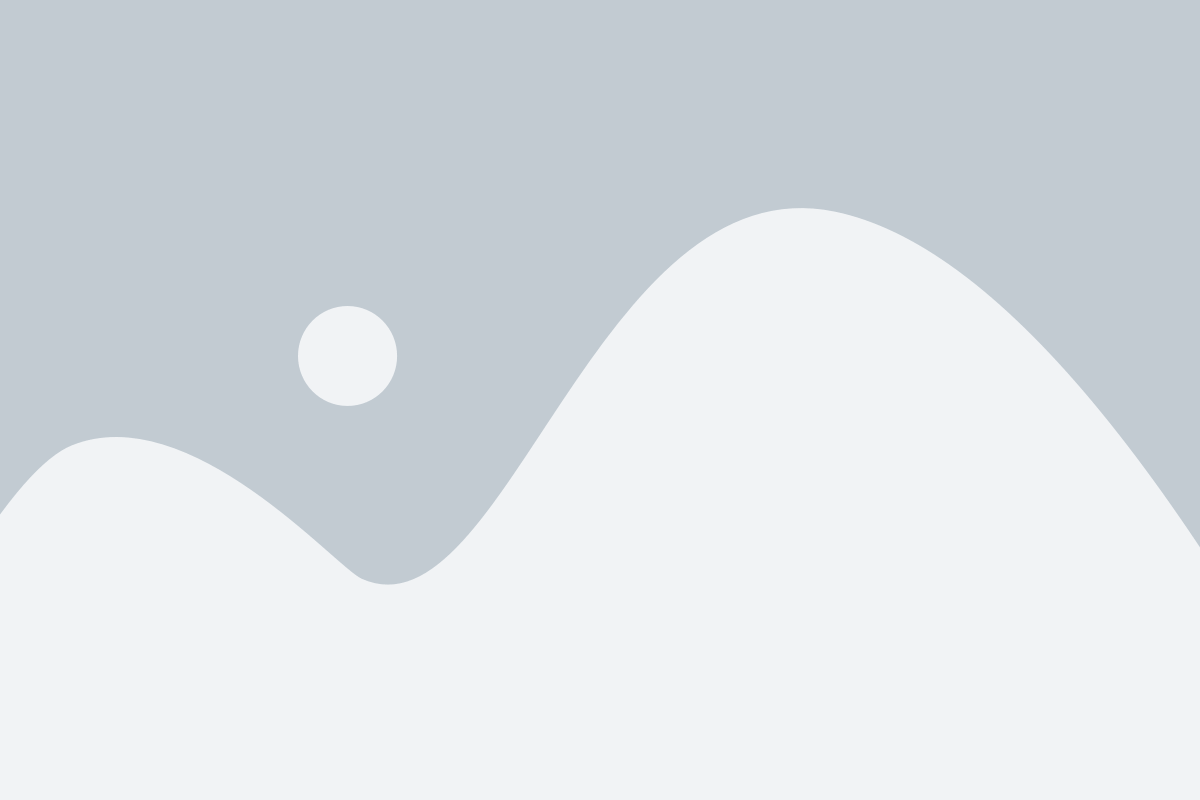

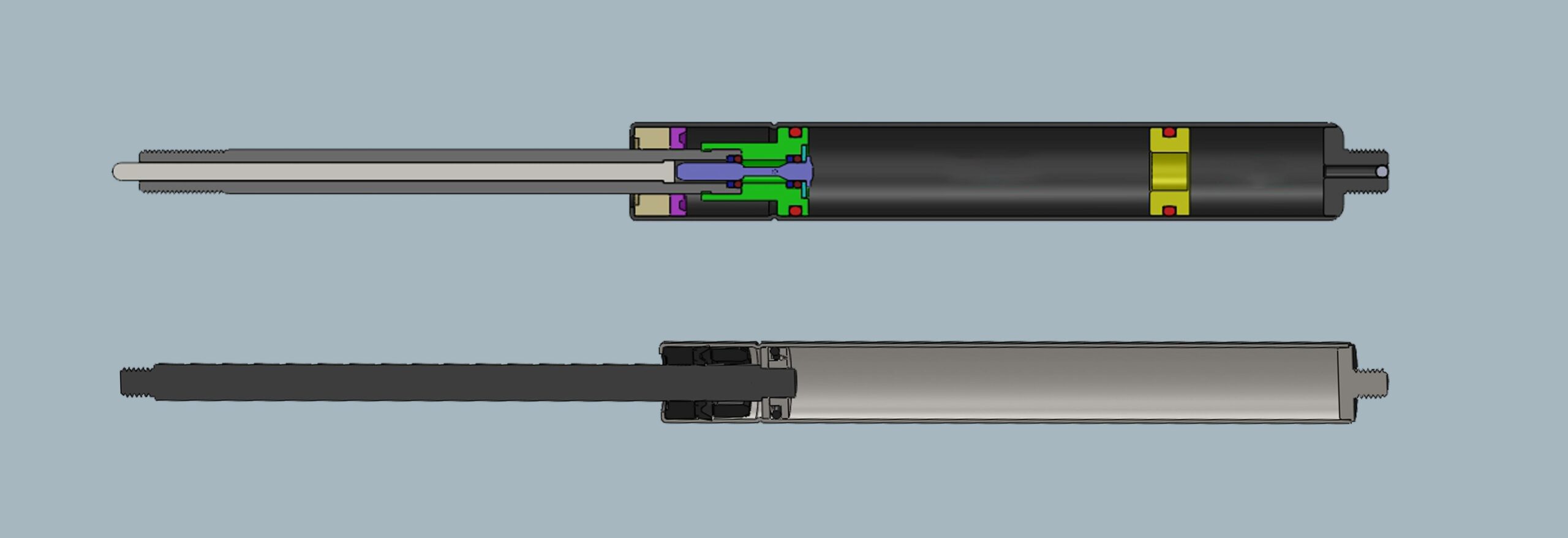

What Exactly Do Dampers Do?

Dampers function as motion controllers:

-

Working Mechanism

- Hydraulic oil flows through valves

- Resistance created to movement

- No stored energy (oil-only models)

-

Performance Features

- Control speed in one/both directions

- Prevent sudden impacts

- Create smooth deceleration

-

Common Uses

- Slowing cabinet door closure

- Elevator safety systems

- Heavy machinery protection

- Vehicle seat movement control

Side-by-Side Technical Comparison

| Characteristic | Gas Spring | Damper |

|---|---|---|

| Primary Function | Generate force | Control speed |

| Energy Storage | Yes (compressed gas) | No (oil-only) |

| Direction | Push/Pull | Push and/or Pull |

| Force Curve | Near-constant | Velocity-dependent |

| Cycle Life | 50,000+ cycles | 100,000+ cycles |

| Temperature Sensitivity | Moderate | Low |

When Would You Use Both Together?

Many applications benefit from combination systems:

-

Simultaneous Needs

- When lifting requires initial assist

- Then needs slowing before stop

- Example: heavy hatches/doors

-

Safety Applications

- Gas spring lifts weight

- Damper prevents rapid fall

- Example: medical equipment

-

Precision Systems

- Smooth movement initiation

- Controlled deceleration

- Example: robotic arms

At JP, we provide both dampers and gas springs tailored to your exact requirements. Browse our catalog or contact info@jpgasspring.com for hybrid solutions.

Conclusion

While dampers and gas springs both manage motion, their core purposes differ fundamentally: one creates movement, the other controls it. Proper selection depends on whether your application needs force assistance or speed regulation.