Do's and don'ts of gas spring

Below is a suggestion list when you design the gas spring on your application and mount a gas spring.

Do (When design)

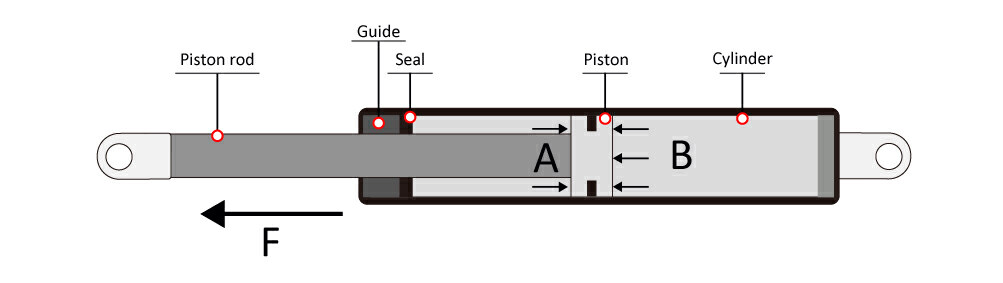

– Do consider the using temperature before confirming the force.

Usually, we designed the force(F1) at the 20℃ standard temperature. If the temperature increases, the force will also increase 4%~10% per 10℃.

– Do consider the end fitting type.

If possible, we recommend choosing the ball joint type. This will reduce the happens of the lateral force.

– Do design a stop to avoid the motion extremes of the struts stroke.

– Do use the stainless steel gas spring in a corrosive environment.

Do (When mount)

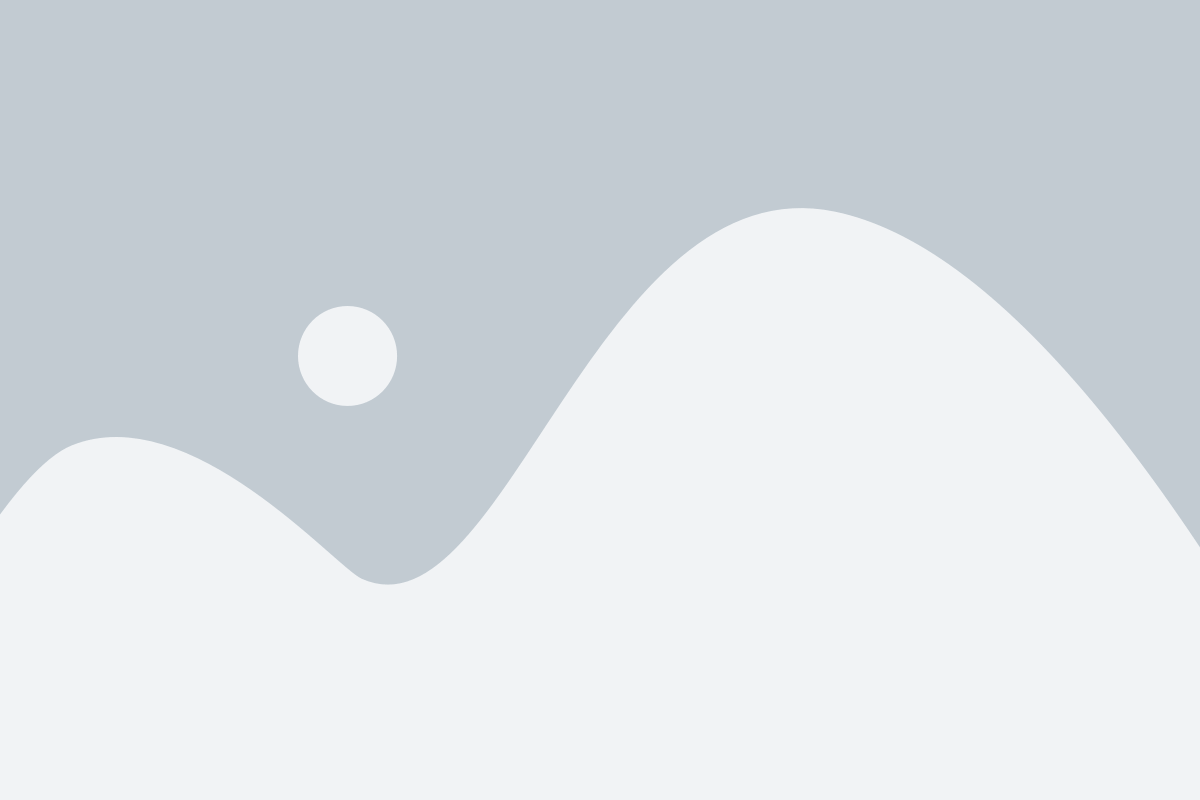

– Do mount or store the rod facing down.

This will lubricate the seal and will improve the damping effect, and reduce the speed of the force loss for a long time store.

– Do fully tighten the end fitting and keep the fitting in line.

It will avoid falling and misalignment.

– Do keep the gas spring in a clean environment if possible.

Don’t

– Don’t make lateral forces (side load) on the piston rod.

Like, pushing, rubbing, vibrations, etc.

– Don’t take the gas spring as a motion stop.

This will shorten the seal age.

– Don’t use the gas spring for more than 15cycles/min.

– Don’t use unprofessional equipment to test the force, like the vice.

– Don’t try to re-inflate the gas or reduce the gas spring’s force.

– Don’t puncture, scratch, dent, chip, bend, paint, wash, or incinerate.

Hope this list will help you during the design or mounting. For more questions, please feel free to contact us.