Gas springs are essential in many mechanical systems, but without proper damping, they can cause damage and noise. End damping is the solution to these problems.

End damping in gas springs reduces the speed of the piston rod at the end of its extension, preventing hard collisions, reducing noise, and extending the life of the spring. Different damping levels are available to suit various applications.

Understanding the importance of end damping can help you choose the right gas spring for your needs. Let’s dive deeper into how it works and what options are available.

How Does End Damping Work in Gas Springs?

End damping is a crucial feature that controls the movement of the piston rod at the end of its extension. Without it, the spring could damage itself and the equipment it’s part of.

End damping slows the piston rod’s movement before it fully extends, preventing hard impacts, reducing noise, and increasing the lifespan of the gas spring. Different damping levels can be chosen based on specific needs.

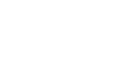

The Mechanism Behind End Damping

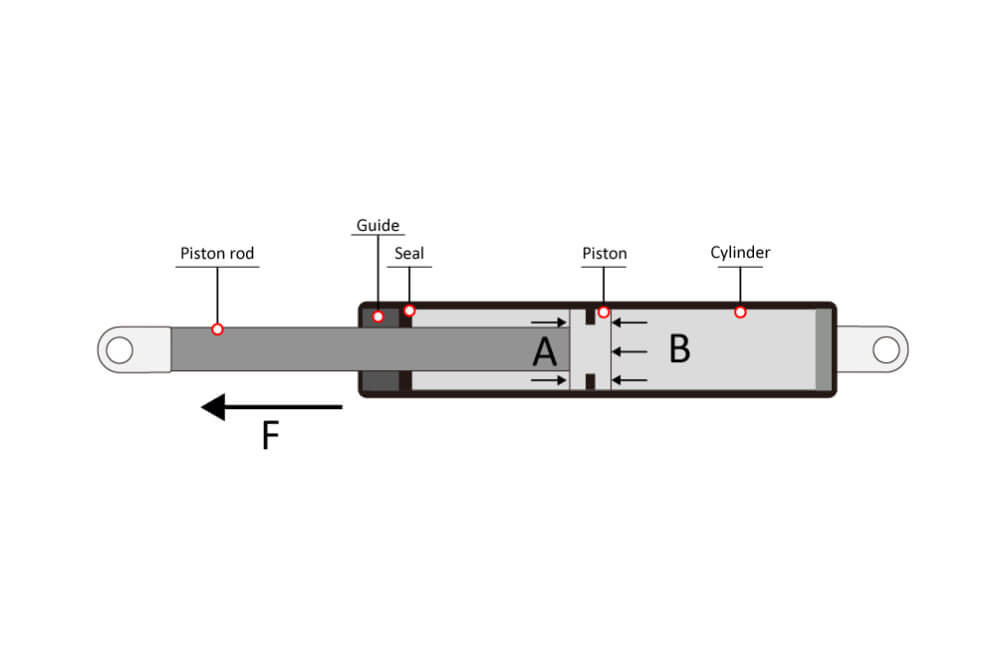

End damping works by creating resistance within the gas spring as the piston rod approaches the end of its travel. This resistance slows down the rod, preventing it from slamming into the end of the cylinder. The damping effect is achieved through internal valves or other mechanisms that control the flow of gas inside the spring.

Benefits of End Damping

The primary benefits of end damping include:

- Protection: Reduces impact force, preventing damage to the spring and machinery.

- Noise Reduction: Provides smoother and quieter operation.

- Extended Lifespan: Minimizes mechanical stress, increasing the spring’s durability.

Choosing the Right Damping Level

Different applications require different levels of end damping. For example:

- Heavy-Duty Industrial Machines: Require stronger damping.

- Lighter Applications (e.g., Car Trunks): May need minimal damping.

JP offers various damping levels:

- No Damping: Fast speed with no deceleration.

- Normal Damping: Balanced deceleration for most applications.

- Reinforced Damping: Stronger deceleration for heavy-duty use.

Installation Considerations

For optimal performance:

- Install the gas spring with the piston rod facing downward.

- Ensure proper alignment and secure mounting.

How to Select the Right End Damping for Your Application?

Selecting the right end damping level is essential for the optimal performance of your gas spring. The wrong choice can lead to inefficiency or damage.

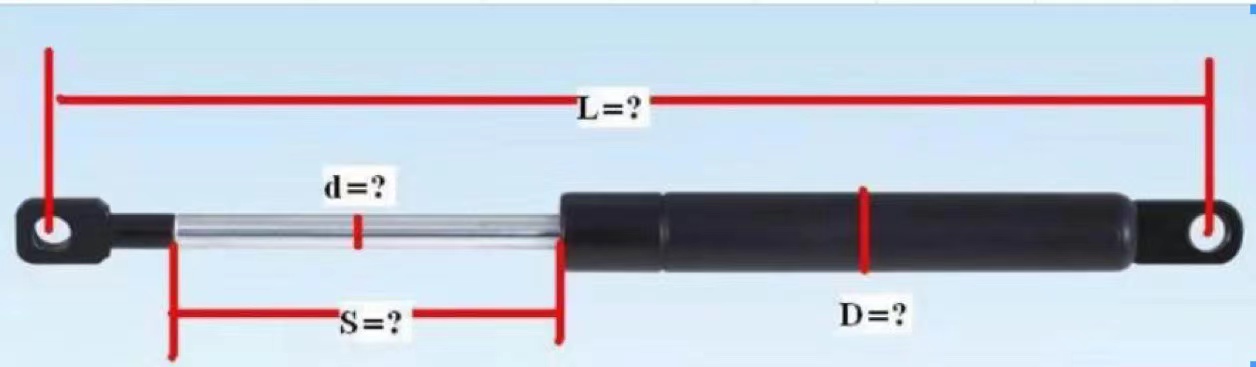

To select the right end damping, consider the speed of the piston rod and the specific needs of your application. JP offers different damping levels and model codes to help you make the right choice.

Understanding Damping Levels and Model Codes

JP’s damping options are indicated by model codes:

- "0": Fast speed with no end damping.

- "1": Fast speed with normal end damping.

Factors to Consider When Choosing Damping

When selecting the damping level, consider:

- Application Type: Heavier applications may require stronger damping.

- Operating Environment: Damping can reduce noise in sensitive environments.

- Desired Lifespan: Choose damping that minimizes wear and tear.

Custom Damping Solutions

If standard damping levels don’t meet your needs, JP can provide custom solutions tailored to your application’s unique requirements.

Conclusion

End damping is a vital feature in gas springs that enhances performance, reduces noise, and extends lifespan. By understanding and selecting the right damping level, users can optimize their equipment’s functionality.

--