Installing gas springs correctly ensures optimal performance and longevity. Understanding the installation process and key considerations is essential for achieving the desired functionality.

Gas springs should be installed with the piston rod facing downward for the best damping effect. Additionally, proper selection of connecting parts, avoidance of side forces, and protection against damage are crucial for reliable operation.

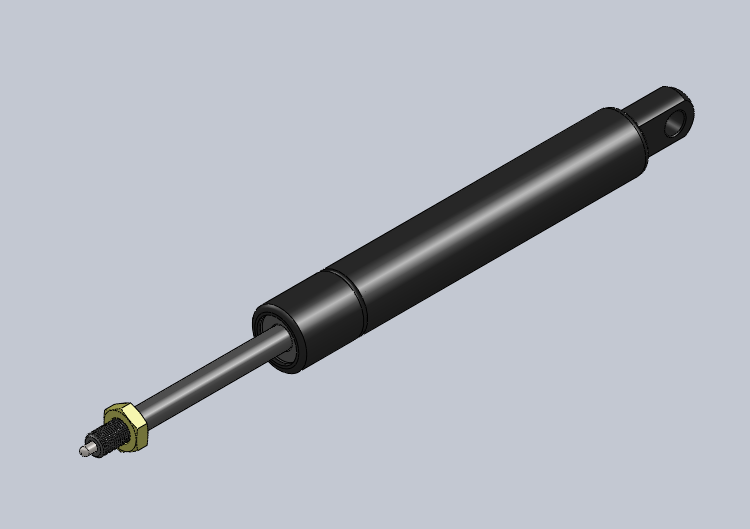

What is the Recommended Installation Direction for Gas Springs?

Gas springs are typically installed with the piston rod facing downward to ensure optimal damping performance. However, Bansbach gas springs include an integrated grease chamber, allowing for installation in any position.

-

Best Practice:

- Install with the piston rod downward for the best damping effect.

- End damping only works when the piston rod faces downward.

-

Flexibility:

- Bansbach gas springs can be installed and stored in any position.

How Do Connecting Parts Affect Gas Spring Installation?

Connecting parts influence the total installation length and overall performance of gas springs. Choosing the right connectors is essential for proper functionality.

-

Types of Connecting Parts:

- Joint eyes (Gelenkaugen): Measure from hole center to hole center.

- U-clamps (Gabel- und Gelenkköpfen): Measure from hole center to hole center.

- Threaded ends (Gewinde): Exclude the length of the thread itself.

-

Impact on Installation:

- Ensure the total installation length includes the length of connecting parts.

What Are the Key Considerations to Avoid Damage?

Protecting gas springs from damage during installation and operation is critical for their performance and safety.

-

Avoid Side Forces:

- Gas springs should not be exposed to tilting or side forces.

- Use appropriate connecting parts to prevent improper loading.

-

Protect Piston Rods:

- Do not paint the piston rod.

- Shield it from impacts, scratches, dirt, and corrosive substances.

-

Inspect for Damage:

- Check for visible damage (e.g., bent piston rod, dented cylinder).

- Release internal pressure before dismantling or using damaged gas springs.

Why Must Gas Springs Be Maintenance-Free??

Gas springs are designed to operate without maintenance, ensuring long-term reliability.

-

Maintenance-Free Design:

- Do not grease or oil the piston rod.

- Avoid unnecessary interventions that could compromise performance.

-

Durability Tips:

- Use mechanical limit stops for high load applications.

- Consult Bansbach for permanent stop solutions.

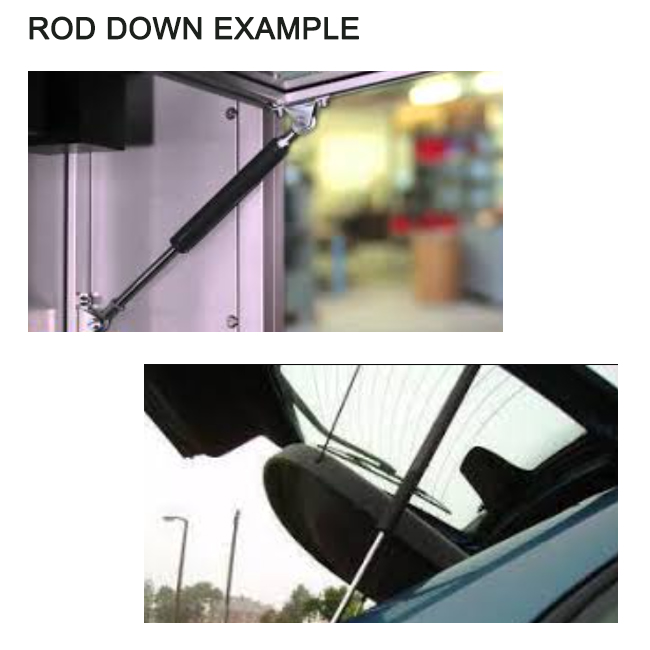

How to Calculate the Correct Installation Length?

Calculating the installation length involves considering the extended length of the gas spring and the connecting parts.

-

Calculation Steps:

- Measure the total length when the piston rod is fully extended.

- Add the length of the connecting parts.

-

Example:

- Minimum extended length (EL1) = Extended length of gas spring + length of connectors.

Conclusion

Proper gas spring installation ensures optimal performance and durability. Key practices include installing with the piston rod downward, selecting appropriate connecting parts, and protecting against damage.