China Reliable Stainless Steel Gas Spring Manufacturer

Get Factory Price Start From 100pcs

As one of China’s best gas spring manufacturers, JP strives to produce every single gas spring that is high-quality and durable for you.

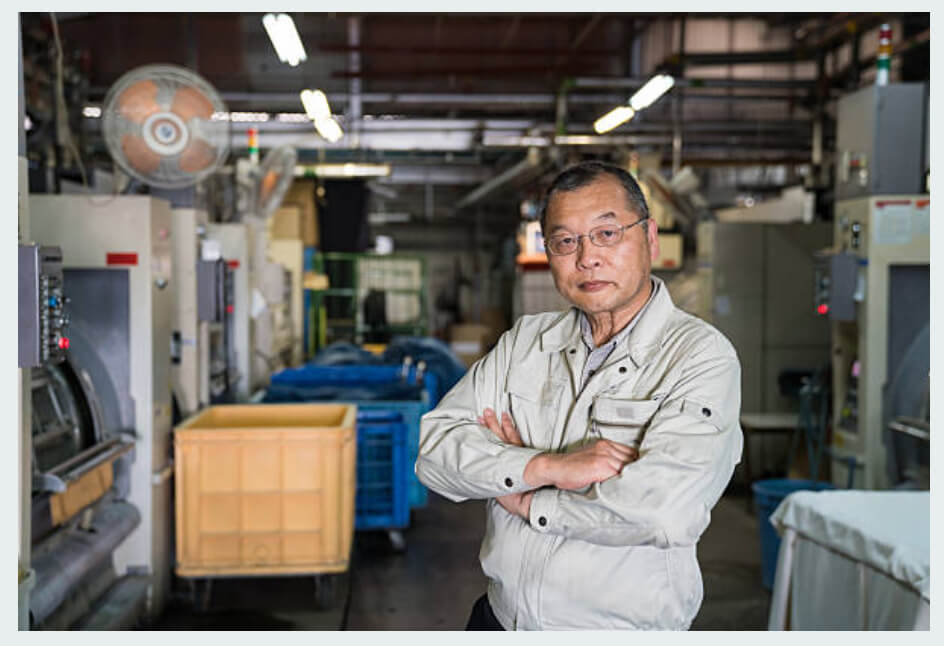

People Who Trust Us

Top Quality Stainless Steel Gas Springs

What Sets Us Apart

We Don’t Believe Shortcuts

20+ Years

Our gas spring experts who have 20+ years of experience are ready to give professional technical support and design services to you.

<100 PPM

German standard production lines and test equipment, to meet the requirements in the US and European countries. Our reject ratio is always less than 100ppm on the customer side.

IATF 16949

We strictly carry out ISO9001 quality management in daily activities, which becomes a common sense and fundamental mindset in our daily operations. We are also upgrading to IATF 16949 quality management system.

>50,000 life cycles

JP gas springs can pass the SGS 50k life cycles test(some models can achieve 100k-180k cycles), and salt spray test of 500 hours, and comply with RoHS and REACH.

Do Ordinary Things Extraordinary

Automated Manufacturing

50+ Million pcs Produced And Counting

JP offers you the choice of various types of gas springs, including compression, locking, stainless steel, tension/traction, and dampers. If you have customized needs, we are also happy to design and prototype them.

Stainless Steel Gas Springs For Harsh Environments

JP design and manufacture stainless steel gas springs for the most demanding environments. We use high-quality 316L or 304 stainless steel materials, offering exceptional corrosion resistance, strength, and durability.

Stainless steel gas springs offer several key advantages over traditional gas springs:

Corrosion resistance

Ideal for marine, offshore, food processing, and pharmaceutical environments.

Durability and longevity

Provides reliable performance and a longer service life.

Aesthetic appeal

Offers a sleek appearance where visual appeal matters.

Superior Quality In Every Tiny Detail

At JP, our commitment to exceptional gas springs is reflected in:

High-grade materials

We use premium 316L and 304 stainless steel for corrosion resistance, strength, and durability.

Advanced manufacturing

State-of-the-art techniques and machinery ensure precision and reliability.

Rigorous quality control

Strict measures guarantee compliance with industry standards.

Industry certifications

Adherence to ISO9001 and implementing IATF 16949 certifications.

Don't Take Our Word for it

Have a first-hand look at how our services and gas springs solved the various demands of our trusted and prestigious clients.

Our Successful Cases In Different Industries

JP has full experience with stainless steel gas springs to support our clients from different industries like Marine Equipment, Food Processing and Pharmaceutical Industry, Medical Equipment, and so on, Our stainless steel gas springs are successfully used in boat seats, machinery covers, hatch covers, cargo bay doors, and access panels, etc.

Marine and Offshore Equipment

Stainless steel gas springs’ corrosion resistance and durability make them ideal for hatch covers, access doors, and boat seats in marine and offshore environments.

Food Processing and Pharmaceutical Industry

With their cleanliness and resistance to corrosive substances, stainless steel gas springs are suitable for machinery covers, conveyor systems, and cleanroom applications in food processing and pharmaceutical industries.

Medical and Healthcare Equipment

Stainless steel gas springs’ corrosion resistance and durability make them ideal for hatch covers, access doors, and boat seats in marine and offshore environments.

Aerospace and Defense Industry

Stainless steel gas springs are used in aerospace and defense applications, such as access panels, equipment doors, and cargo bay doors, due to their strength and durability.

Contact us Now

Find the optimal gas springs for your application with JP, and contact us to get a quote and 2 free samples.

Choosing The Right Gas Spring

You can confidently select the right gas spring to ensure optimal performance and long service life.

Tell Us Your Application

Consider the specific use of the gas spring, such as lifting, lowering, or counterbalancing.

Force & Stroke

Consider the weight of the object being moved, and The distance the gas spring will need to travel.

Mounting & End Fittings

Identify the mounting points and hardware required for your application, consider the factors such as angle, orientation, and ease of installation.

Fill Out The Form to Consult with JP gas spring experts Now!

Copyright © 2022, JP. All rights reserved.