Ever struggled with mechanical designs requiring smooth pulling force instead of pushing? Gas traction springs solve this exact challenge in various industries.

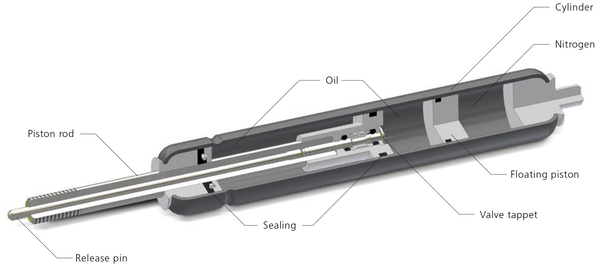

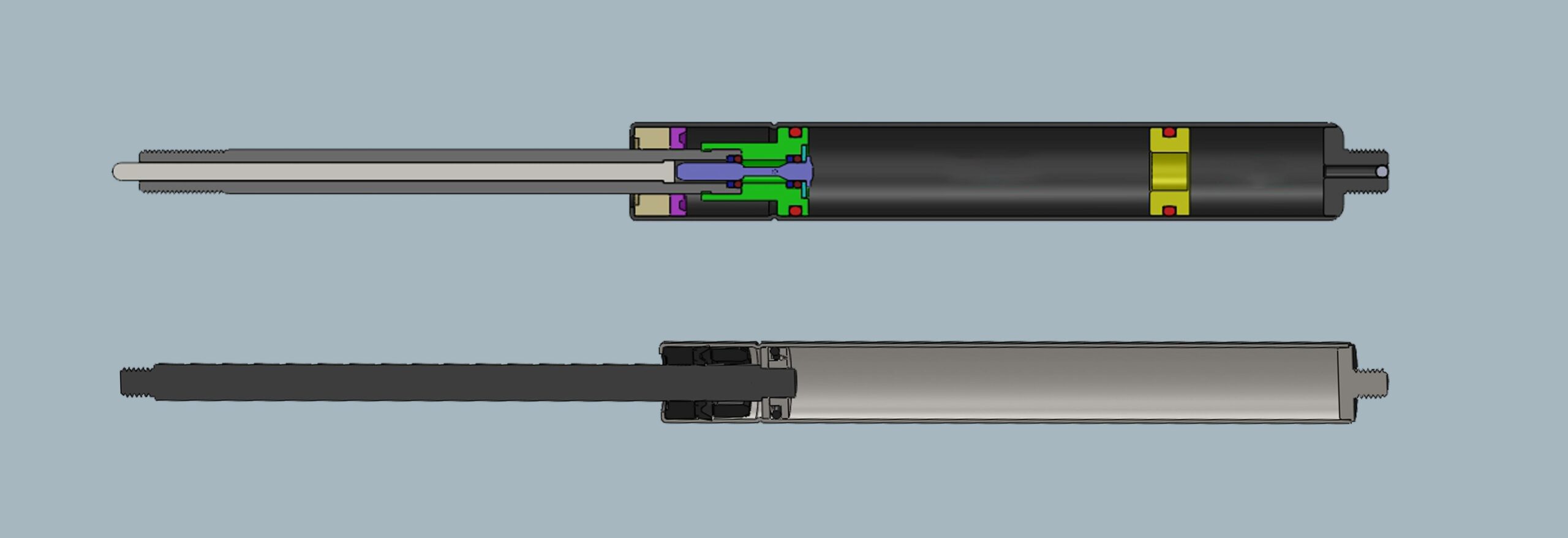

Gas traction springs are specialized gas springs that generate controlled pulling force rather than pushing force. They use compressed nitrogen to create retraction power, with options for damping and locking features. Commonly used in medical, furniture, and aerospace applications where precise pulling motion is required.

How Do Gas Traction Springs Differ From Standard Gas Springs?

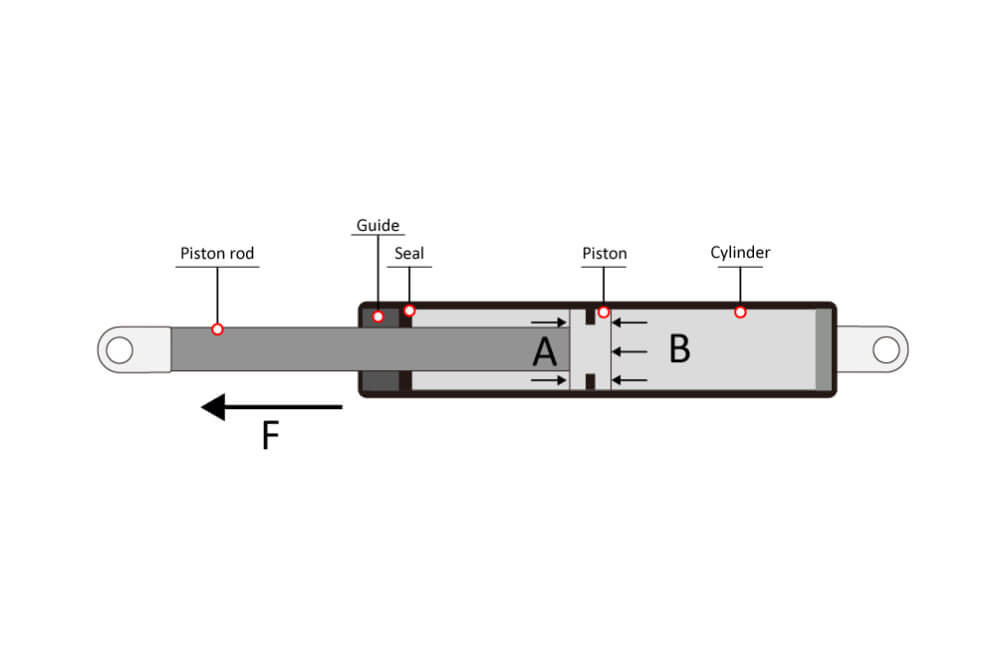

Understanding the core differences helps select the right component:

-

Force Direction

- Standard gas springs: Push outward

- Traction springs: Pull inward

-

Typical Applications

- Standard: Lifting lids/hatches

- Traction: Retracting mechanisms

-

Mounting Orientation

- Standard: Extended position stores energy

- Traction: Retracted position stores energy

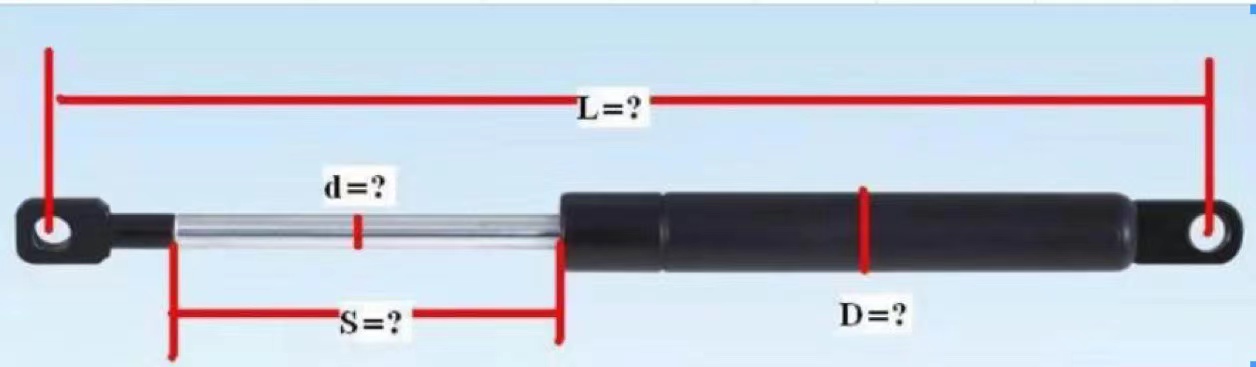

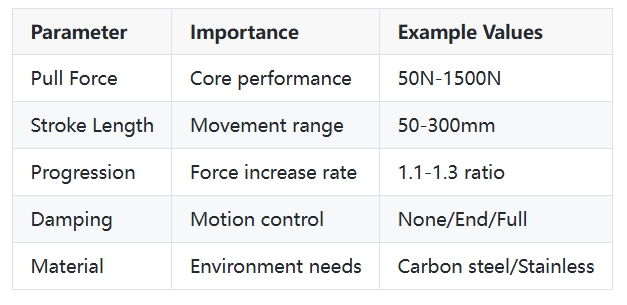

Key Technical Specifications

When ordering gas traction springs, engineers should specify:

Our JP gas traction springs offer customizable options for your exact needs. Download our product catalog or contact info@jpgasspring.com for technical support.

Common Applications of Gas Traction Springs

These unique springs solve problems across industries:

-

Medical Equipment

- Retractable scanner arms

- Adjustable hospital beds

- Physical therapy devices

-

Functional Furniture

- Fold-down wall beds

- Retractable tables

- Space-saving mechanisms

-

Industrial Machinery

- Automated retraction systems

- Safety curtain returns

- Equipment positioning

Lockable Gas Traction Springs Explained

Special models offer enhanced functionality:

-

Working Principle

- Contains internal locking mechanism

- Maintains position when engaged

- Releases smoothly when unlocked

-

Key Benefits

- Position holding without energy

- Safety in vertical applications

- Precise movement control

-

Technical Considerations

- Requires special fittings

- Higher maintenance needs

- Available in various force ratings

Stainless Steel vs Standard Models

Material selection affects performance:

-

Standard Carbon Steel

- Cost-effective solution

- Good for indoor use

- Standard force range

-

Stainless Steel Options

- Corrosion resistant

- For harsh environments

- Food/medical compatible

Installation and Maintenance Tips

Proper handling ensures optimal performance:

-

Mounting Guidelines

- Avoid side-loading

- Use proper fittings

- Consider stroke direction

-

Maintenance Practices

- Regular visual checks

- Clean rod surfaces

- Monitor damping behavior

Conclusion

Gas traction springs provide unique pulling solutions where conventional gas springs can't. Their customizable features make them ideal for precise motion control applications requiring retraction force.