Gas springs are indispensable in the automotive industry, providing controlled movement without external energy. They ensure safety, smooth operation, and reliability in various vehicle components.

Gas springs are widely used in the automotive industry for applications like hoods, trunk lids, tailgates, and adjustable seats. They offer controlled movement, safety, and durability without requiring external power sources.

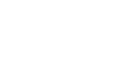

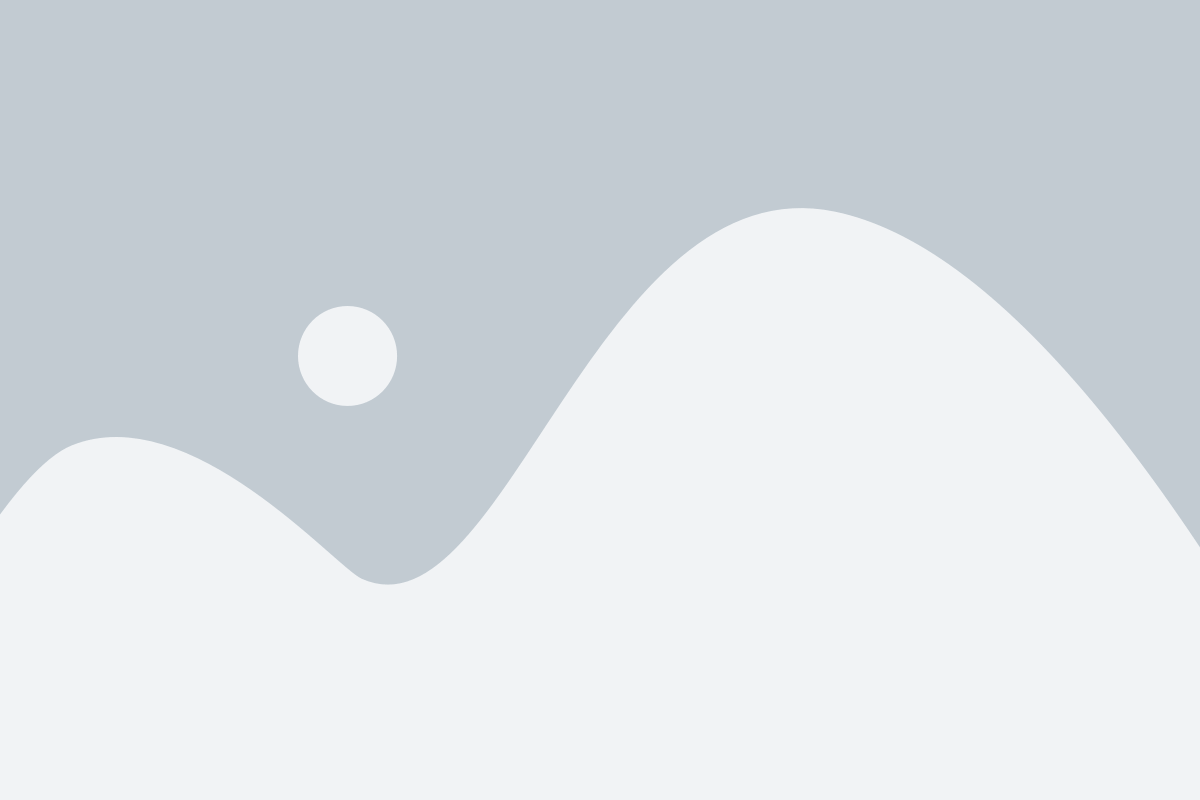

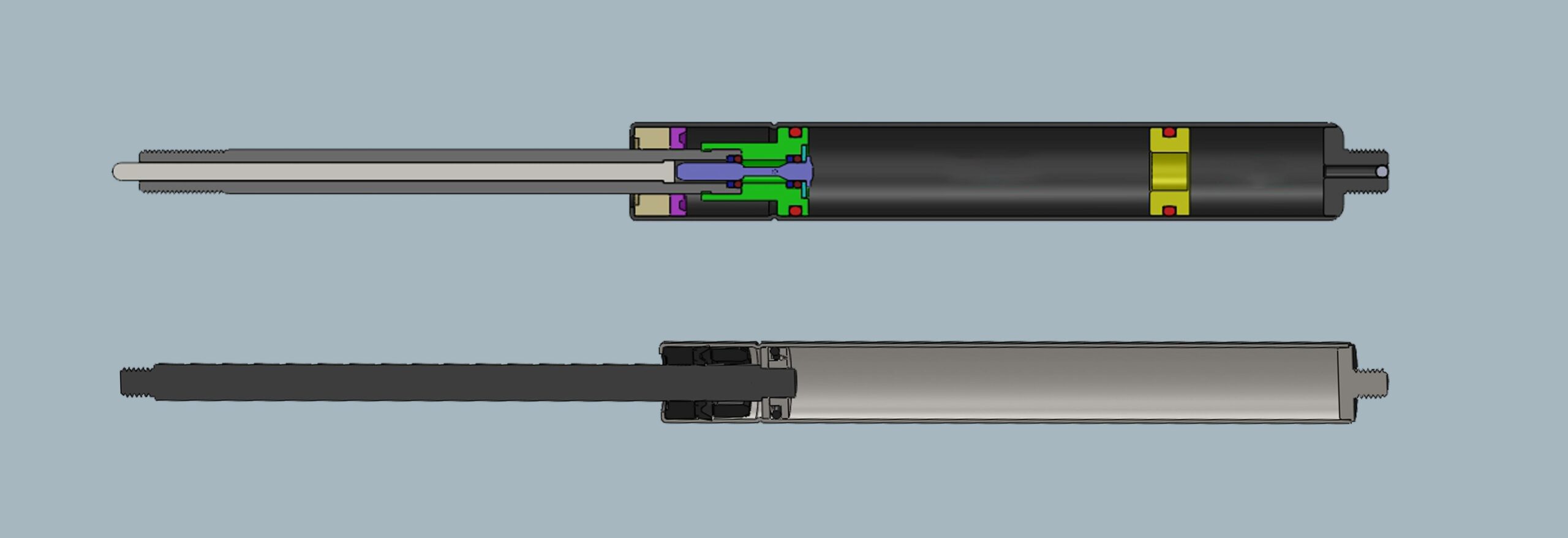

How Do Gas Springs Provide Controlled Movement?

Gas springs use compressed nitrogen gas to generate force, enabling controlled lifting, lowering, and positioning of vehicle components. This eliminates the need for external energy sources.

-

Functionality

- Gas springs provide lift or support for heavy components like hoods and trunk lids.

- They ensure smooth and controlled opening and closing motions.

-

Applications

- Hoods: Prevent sudden drops and ensure easy opening.

- Trunk lids/Tailgates: Support weight and control closing speed.

- Adjustable seats: Enable smooth height and angle adjustments.

What Makes Gas Springs Safe and Reliable?

Gas springs enhance safety by preventing sudden movements and reducing noise and vibration. Their durable design ensures long-lasting performance.

-

Safety Features

- Prevent unexpected drops of heavy components like hoods and trunk lids.

- Reduce noise and vibration during operation.

-

Reliability

- High-quality materials and manufacturing processes ensure durability.

- Long service life even under continuous use.

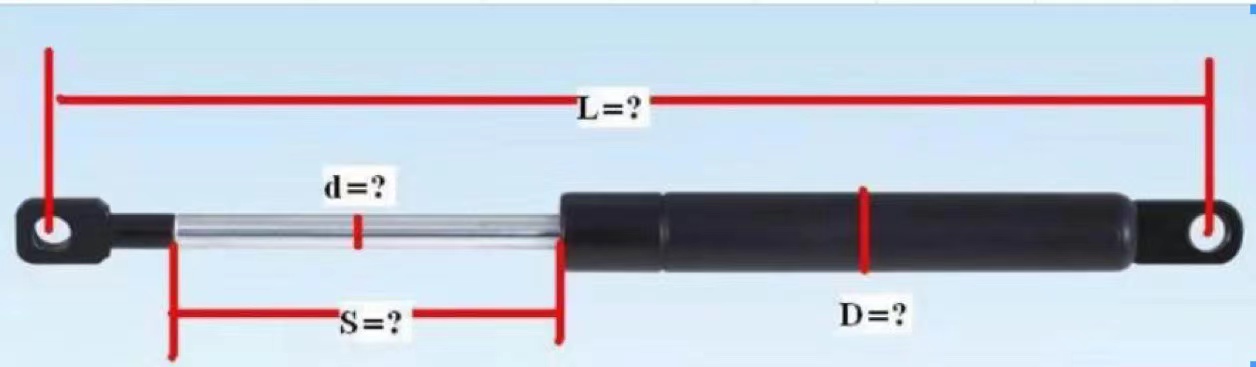

What Types of Gas Springs Are Used in Automotive Applications?

Different types of gas springs cater to specific automotive needs, from standard lifting to locking mechanisms.

-

Standard Gas Springs

- Provide lift and support for components like hoods and trunk lids.

-

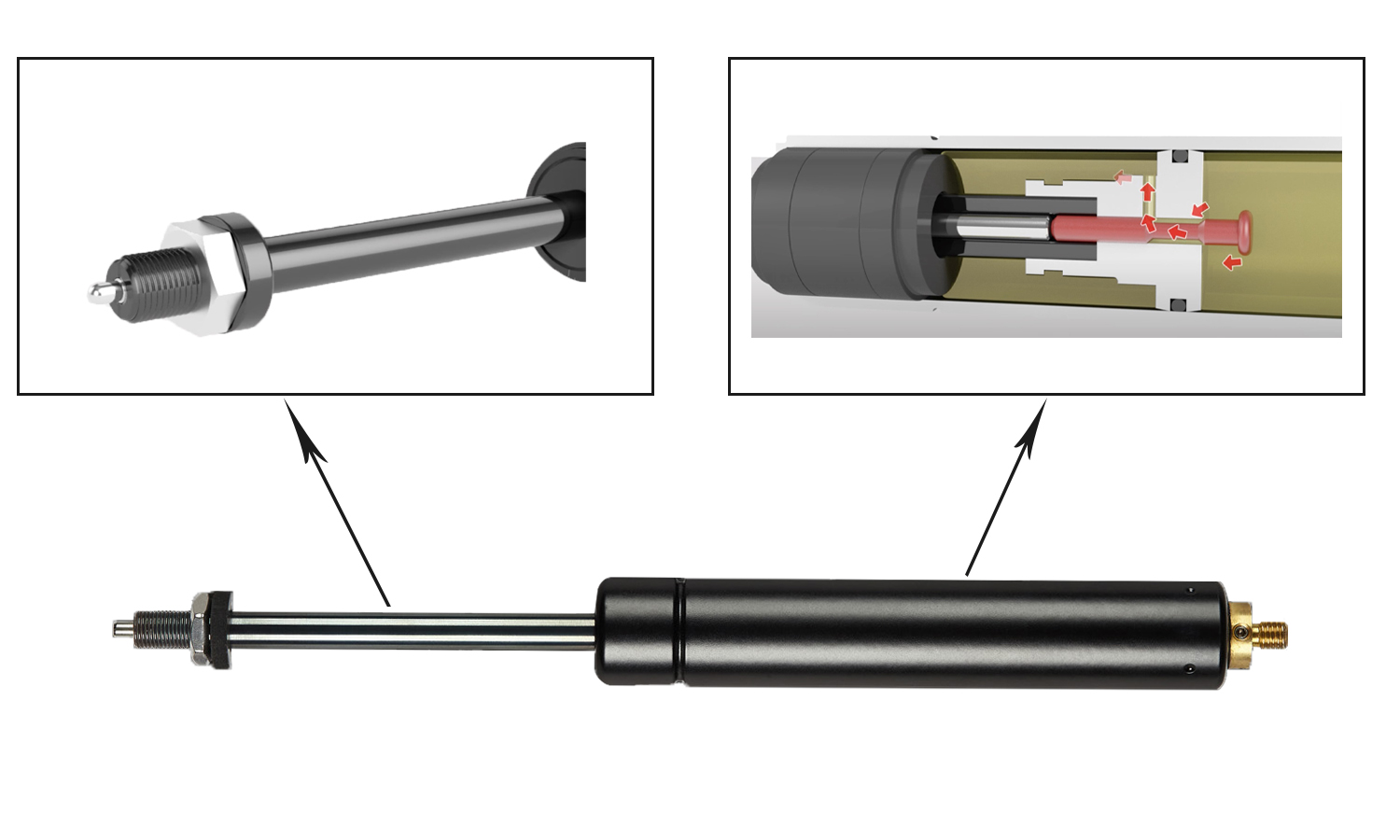

Lockable Gas Springs

- Lock components in specific positions, ideal for adjustable seats.

-

Gas Traction Springs

- Used for pulling motions in specialized applications.

-

Dampers

- Control the speed of movement, often used in high-end vehicles for smoother closing experiences.

Why Are Gas Springs Corrosion-Resistant and Long-Lasting?

Automotive components are exposed to harsh environments, making corrosion resistance and durability crucial.

-

Corrosion Resistance

- Powder-coated cylinders and CeramPro® treated piston rods enhance durability.

- Stainless steel gas springs are ideal for highly corrosive environments.

-

Durability

- Designed to withstand continuous use without performance degradation.

- Rigorous testing ensures long service life.

How Does Customization Enhance Gas Spring Applications?

Gas springs can be customized to fit specific vehicle designs, ensuring optimal performance.

- Tailored Solutions

- Custom dimensions and force ratings to match unique vehicle designs.

- Flexibility in design ensures compatibility with various automotive components.

Conclusion

Gas springs are vital in the automotive industry, offering controlled movement, safety, durability, and customization. They ensure smooth and reliable operation in various vehicle components.