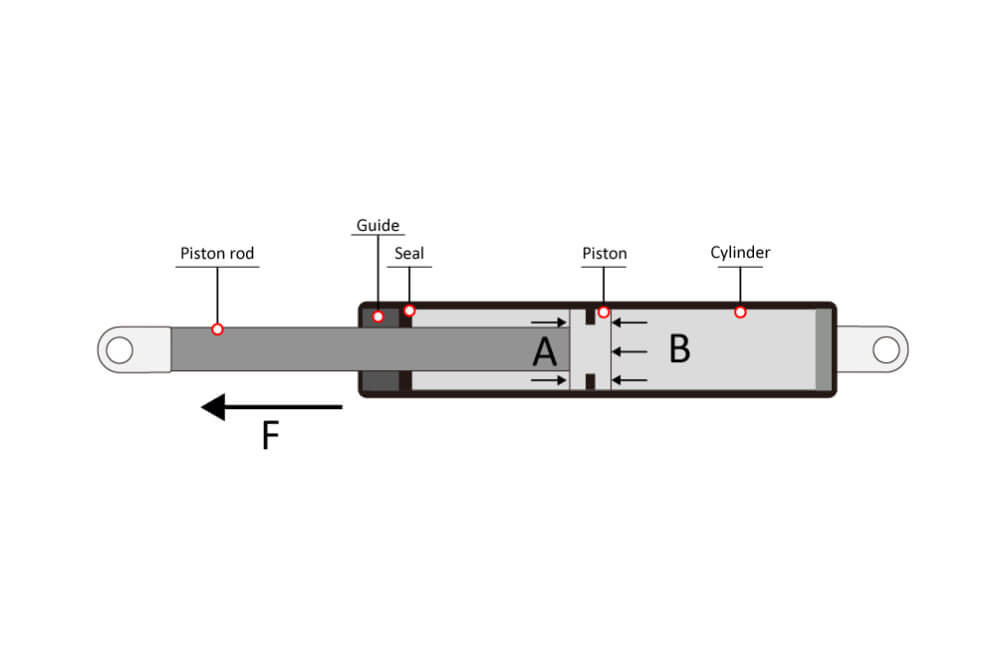

Struggling with inconsistent movement or premature wear in your equipment? The solution lies in understanding how low friction transforms gas spring functionality.

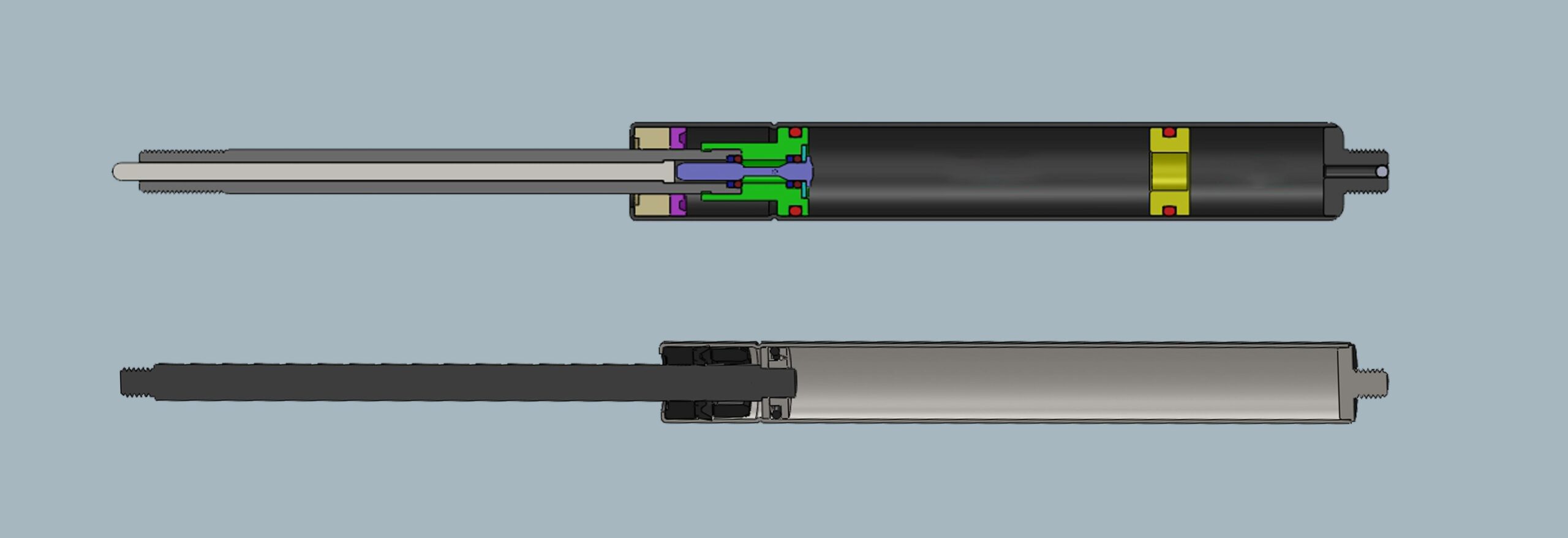

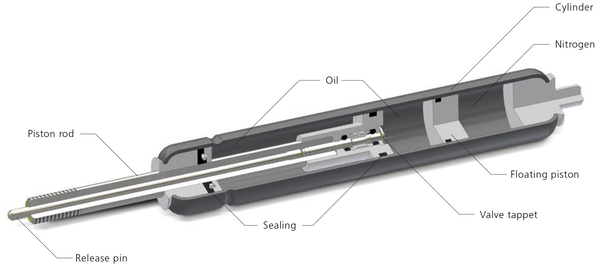

Low friction in gas springs enables precise force control, smooth operation, adjustable speeds, and extended service life. JP achieves this through advanced materials like their patented CeramPro® coating and precision engineering, making their gas springs ideal for applications requiring delicate movement control and long-term reliability.

The 4 Key Benefits of Low Friction Design

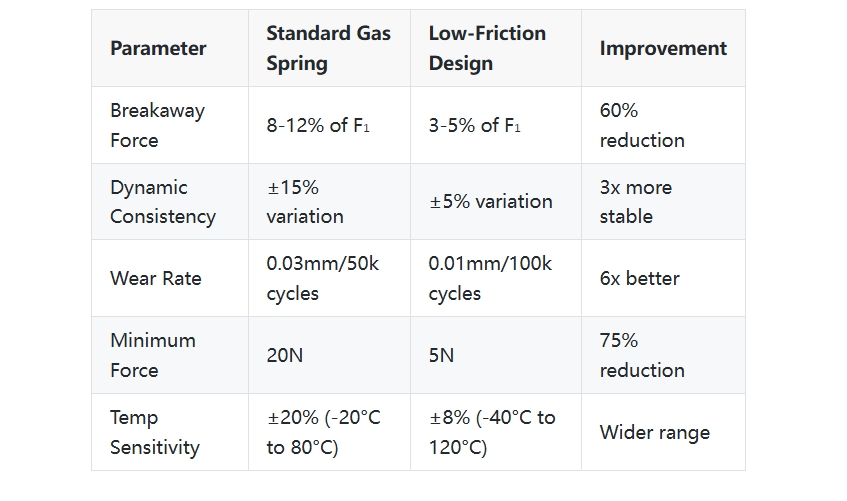

1. Ultra-Precise Force Control

- Achieves extension forces as low as 5N

- Enables delicate motion in medical/surgical equipment

- Provides consistent force output throughout stroke

- Application Example: Microscope positioning systems

2. Reliable Locking Mechanisms

- Reduces lock engagement force by up to 40%

- Ensures positive engagement/disengagement

- Extends lock mechanism lifespan

- Technical Insight: Reduces stick-slip phenomenon

3. Adjustable Speed Characteristics

- Low friction amplifies nozzle adjustment effects

- Enables speed variations up to 3:1 ratio

- Provides smoother acceleration/deceleration

- Engineering Note: Works with ISO VG 15-68 hydraulic oils

4. Enhanced Component Longevity

- Reduces rod seal wear by 70-80%

- Maintains performance over 100,000+ cycles

- Lowers total cost of ownership

- Case Study: Automotive hood supports showing 10+ year lifespan

Technical Comparison: Standard vs Low-Friction Gas Springs

Industry-Specific Applications

Medical Equipment

- Radiation therapy positioning

- Surgical robot arms

- MRI table adjustments

Automotive Excellence

- Soft-close tailgates

- Adjustable headrests

- EV battery access panels

Industrial Solutions

- Cleanroom assembly

- Semiconductor handling

- Food processing equipment

For custom low-friction solutions, JP Gas Spring engineers are ready to assist. Contact info@jpgasspring.com or request our application guide.

Maintenance Best Practices

Installation Guidelines

- Always keep rod surface downward

- Use proper alignment fixtures

- Avoid side loads exceeding 5% of F₁

Performance Monitoring

- Quarterly force measurements

- Annual seal inspections

- Regular cleaning of exposed rods

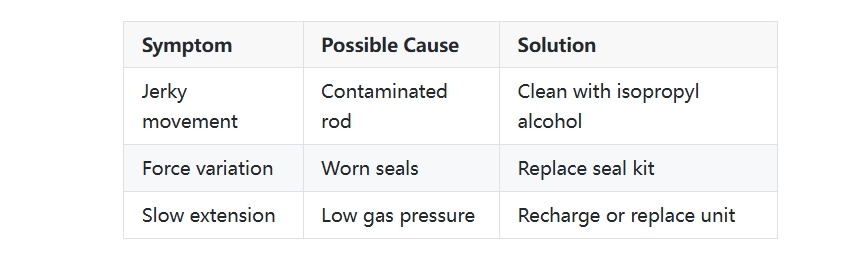

Troubleshooting Tips

The JP Advantage

Our gas springs feature:

- Precision-ground internal components

- Custom tuning for your application

- Global technical support network

Conclusion

Low friction isn't just a specification - it's what enables gas springs to perform consistently in precision applications while lasting years longer than conventional designs. For equipment requiring smooth, reliable motion control, low-friction gas springs deliver measurable performance advantages and long-term cost savings.